Top Rated Oxy Gas Welding Kit for Precision Metalworking and Repairs

Introduction to Oxy Gas Welding Kits

Oxy gas welding, a staple in the metalworking industry, revolves around using an oxy gas welding kit to combine oxygen and a fuel gas—typically acetylene—to produce highly concentrated flames. This method is instrumental in various tasks, such as metal cutting, brazing, and soldering. Understanding the components, safety practices, and maintenance of these kits is vital for anyone looking to use this technology effectively.

What Is an Oxy Gas Welding Kit?

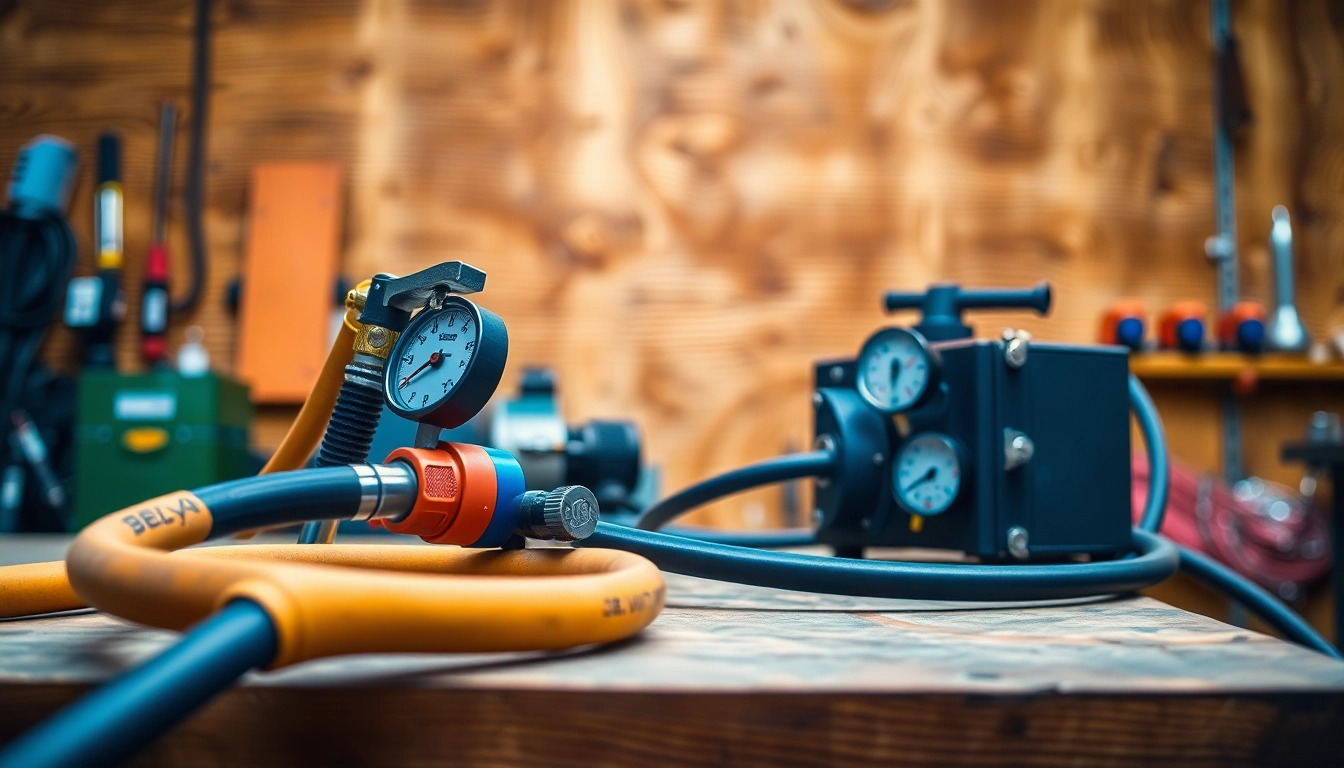

An oxy gas welding kit is a collection of tools designed for welding and cutting metals through the combustion of oxygen and a flammable gas. It typically consists of a welding torch, gas cylinders, hoses, regulators, and nozzles. The combination of these elements allows for precise control over heat application, making it suitable for various applications—from heavy industrial tasks to delicate art projects.

Key Components and Their Functions

- Welding Torch: The welding torch is the heart of the system, used for mixing oxygen and acetylene to create the flame. Different nozzles are available for various tasks, such as welding thicker metals or achieving finer control for intricate work.

- Gas Cylinders: These are pressurized containers that hold oxygen and acetylene. They need to be constructed from durable materials to withstand high pressures and must be handled with care.

- Regulators: Regulators control the flow of gases from the cylinders to the torch, ensuring that the correct gas mixture is delivered for the desired application.

- Hoses: Made from flexible, durable materials, hoses connect the gas cylinders to the torch. They must be inspected regularly for leaks and wear since faulty hoses can lead to dangerous situations.

Common Applications in Metalworking

Oxy gas welding kits are versatile and can be used in numerous applications, including:

- Welding: Joining metals together, particularly in fabrication and repair tasks.

- Cutting: Efficiently slicing through steel and other tough materials, making it ideal for construction and demolition projects.

- Brazing and Soldering: Used for joining metals that may not withstand higher temperatures involved in welding.

- Heating: Preheating metals prior to other welding processes or for reshaping purposes.

Choosing the Right Oxy Gas Welding Kit

Factors to Consider Before Purchasing

Selecting the right oxy gas welding kit hinges on several critical factors that affect performance, safety, and suitability for specific tasks.

- Application: Determine what types of projects you’ll be handling. For instance, heavier welding tasks may necessitate a more robust kit than one intended for light work.

- Brand and Quality: Established brands often provide durable and reliable equipment. Look for reviews and testimonials to gauge performance.

- Price: While budget is a critical consideration, prioritizing quality and safety over price can save money in the long run, as cheaper kits may require frequent replacements.

- Regulations: Always ensure that the selected kit meets local safety standards and regulations, especially for professional use.

Comparison of Various Brands and Models

When venturing into the market for an oxy gas welding kit, various brands provide options ranging from entry-level to professional-grade kits. Some notable brands include:

- Victor: Known for their extensive range of high-quality torch kits, suitable for professional applications.

- Harris: Offers reliable and affordable options that rank highly for both beginners and experienced users.

- Lincoln Electric: Known for durable, performance-driven kits, often led to their popularity in industrial applications.

- Unimig: A brand characterized by innovative designs and practical solutions for both hobbyists and professionals, available on sites like Alpha Weld.

Understanding Price Ranges and Value

Typically, oxy gas welding kits range from about $100 to over $500. Basic kits with fewer components are less expensive, while comprehensive kits with advanced features and high durability can demand higher prices. It’s essential to assess the value concerning your specific needs. For instance, investing in a professional-grade kit can yield better results over time than repeatedly purchasing lower-quality products.

Safety Practices for Oxy Gas Welding

Essential Safety Gear and Equipment

Safety should be the foremost priority when engaging in oxy gas welding. Essential gear includes:

- Welding Goggles: Protects the eyes from bright flames and UV rays emitted during welding.

- Protective Clothing: Fire-resistant jackets, gloves, and long pants to shield skin from sparks and heat.

- Respirator: In poorly ventilated areas, it’s advisable to wear a respirator to avoid inhaling harmful fumes.

- Fire Extinguisher: Keep one nearby to manage any accidental fires that may occur.

Best Practices to Minimize Risks

To maintain a safe working environment, implement these best practices:

- Always conduct pre-checks on your oxy gas welding kit to identify any potential leaks or faults.

- Ensure proper ventilation in the work area to minimize exposure to hazardous fumes and gases.

- Store gases in a designated, secure area away from extreme heat sources or potential ignition points.

- Never work when fatigued; alertness is vital for safety in such potentially dangerous activities.

Emergency Procedures During Welding

Being prepared for emergencies is critical in welding environments. Here are emergency guidelines to follow:

- In case of fire: Activate the nearest fire alarm, use the fire extinguisher, and vacate immediately if the fire escalates.

- For injuries: Know the location of first aid kits and potential emergency contacts. Recognize serious injuries requiring immediate medical attention.

- Gas leaks: If suspicious of a gas leak, shut off the gas supply, leave the area, and contact emergency services.

Maintaining Your Oxy Gas Welding Kit

Regular Maintenance Checks and Cleaning

Regular maintenance enhances the lifespan and safety of your oxy gas welding kit. Key practices include:

- Frequent visual inspections for wear or damage to hoses, regulators, and torches.

- Cleaning the torch tips to prevent obstructions and ensure optimal gas flow.

- Checking connections to ensure they are tight to prevent gas leaks.

Storage Tips to Extend Lifespan

Proper storage prolongs the functionality of your equipment:

- Store gas cylinders upright in a cool, dry location away from sunlight or heat.

- Keep hoses coiled and free from tangles or kinks that may weaken them.

- Store welding tools in protective cases or boxes to prevent damage from external factors.

When to Seek Professional Repairs

If your kit shows signs of damage or poor performance after maintenance attempts, it’s time to seek professional help. Issues such as:

- Persistent gas leaks.

- Inability to achieve proper flame settings.

- Visible damage to regulators or hoses that may compromise safety.

The Future of Oxy Gas Welding

Innovations in Welding Equipment

The welding industry is continuously evolving with advancements in technology. Future innovations may include:

- Smart welding systems with integrated sensors to monitor performance and safety.

- More efficient gas flow technologies to reduce waste and environmental impact.

- Portable, lightweight systems that cater to mobile welding applications.

Comparative Analysis with New Technologies

While oxy-acetylene welding remains popular, newer methods such as MIG and TIG welding offer advantages in speed and efficiency. However, oxy gas welding retains unique benefits, particularly in repair applications due to its versatility and low equipment cost.

Oxy Gas Welding in Modern Industries

Despite the emergence of new welding technologies, oxy gas welding finds its niche in several modern applications, including:

- Automotive repair and fabrication, where precision heating is required.

- Heavy machinery repairs, where oxy-acetylene’s heating efficiency shines.

- Art and design projects, where intricate metal shaping and joining is essential.